How ERP Helps F&B Control Shrinkage (and Cut COGS by ~3%)

In F&B, inventory shrinkage silently erodes margins. In practice, the An Nhien Cafe chain reduced cost of goods sold (COGS) by ~3%, turning several outlets from loss to profit after implementing ERP. This was achieved through daily count-and-reconcile in ERP, which flags variances the same day and cuts stocktake time by 60%+.

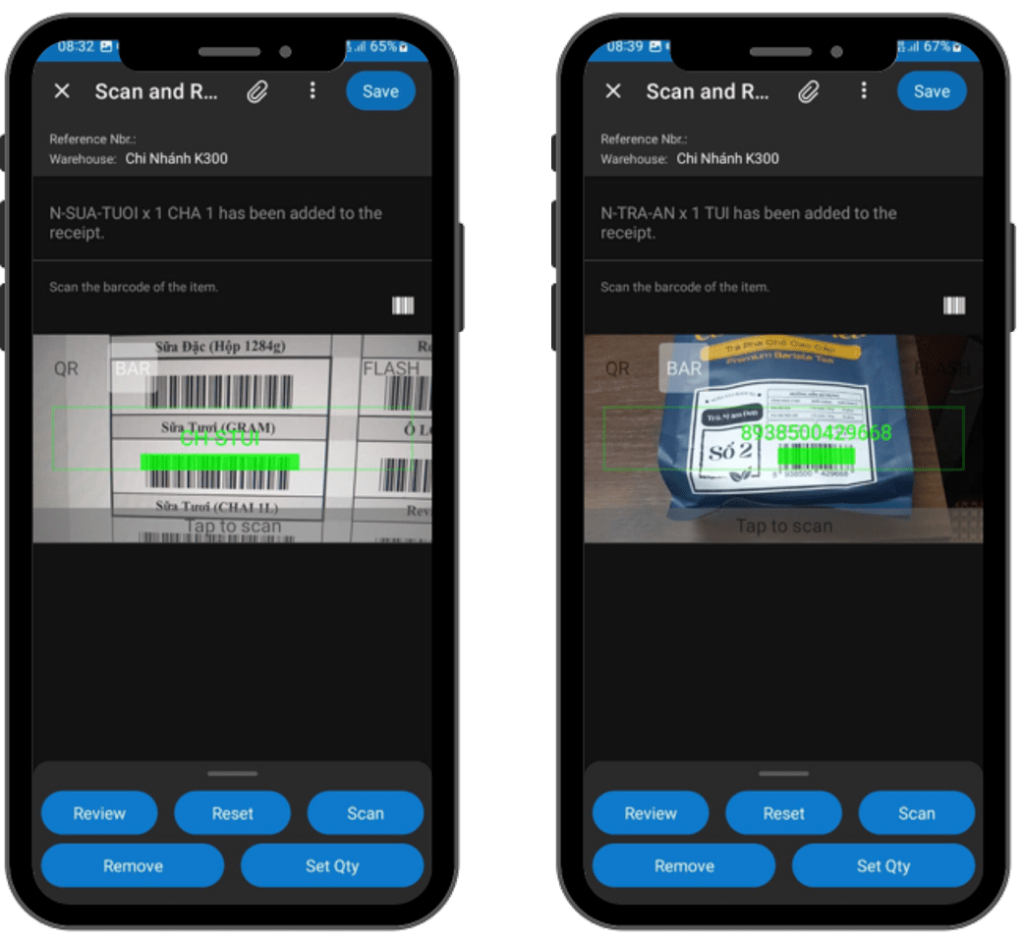

Manual spreadsheets and scattered tools often create count errors and extra paperwork. An F&B-ready ERP (e.g., Acumatica F&B Edition) fixes this with a smart daily inventory cycle plus a mobile barcode app.

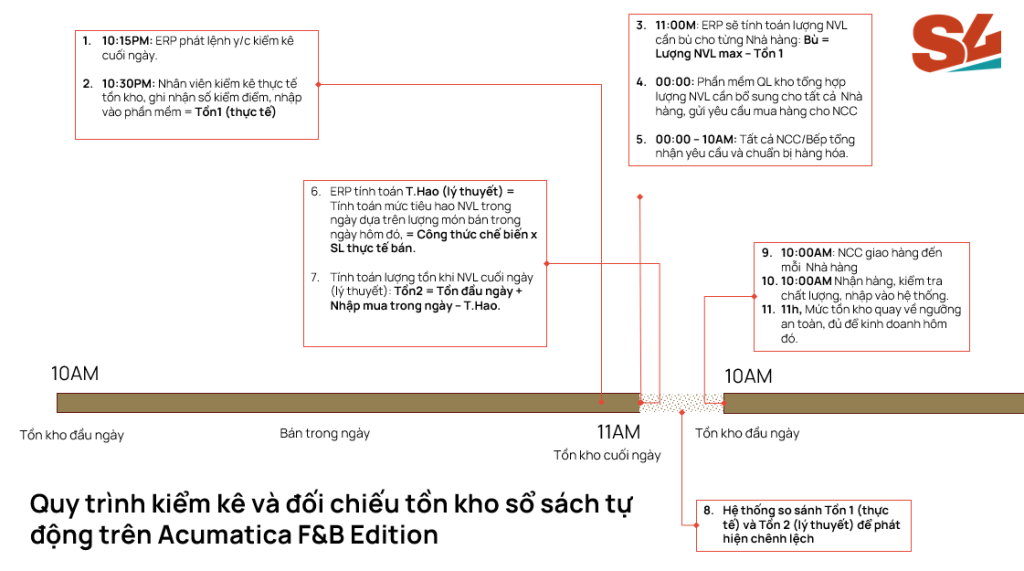

Daily Count & Reconciliation Workflow (End-of-Day)

ERP enforces a daily routine that spots losses in real time and directly lowers raw-material costs:

- All issue/receipt transactions via Mobile App (100% in-store operations)

- Consumption backflush: ERP auto-calculates theoretical consumption from that day’s sales (Theoretical Usage)

- End-of-day count task: ERP reminds staff to perform stocktake

- Physical count: staff record On-Hand (Physical) on the app

- Reconciliation: system compares Physical (Tồn1) vs Theoretical balance (Tồn2) to isolate variances

- Auto-replenishment: ERP consolidates needs and raises purchase requests

- Next-morning delivery: keeps ingredients flowing without disruption

→ With this cadence, you don’t just prevent leakage—you can consistently drive ~3% COGS reduction, materially improving profitability.

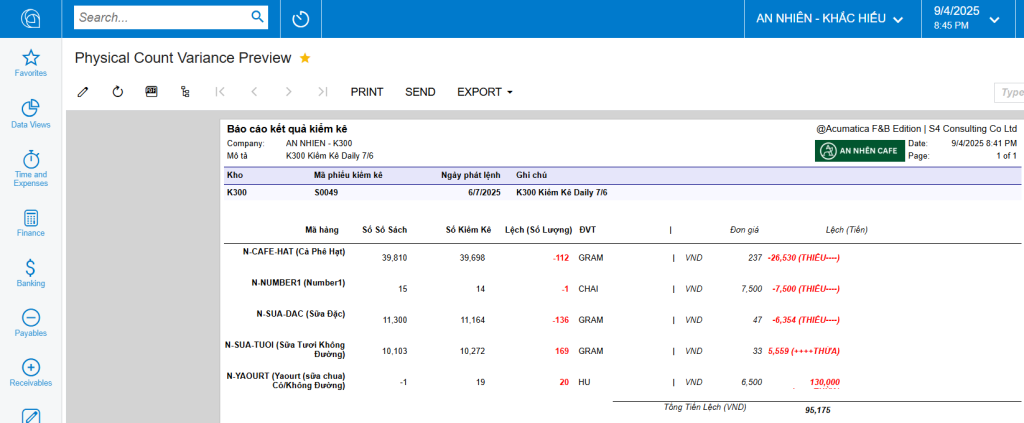

Inventory Variance Report: See Losses, Quantified in Money

ERP outputs a clear variance report—over/short by item and value impact—so managers can take action immediately.

If items like coffee beans or condensed milk show repeated shortages while others are over, the system makes that visible today, not at month-end.

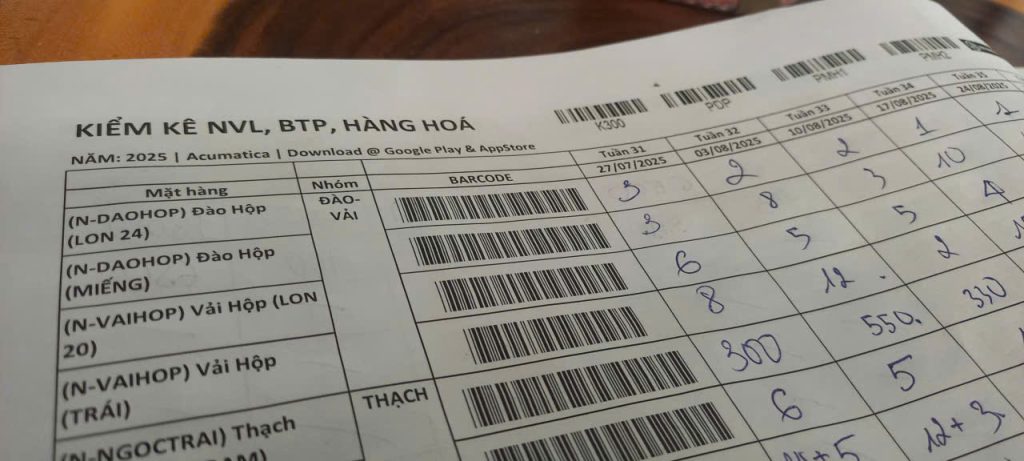

Mobile App & Barcode — Why Stocktakes Become 60%+ Faster

- Scan, don’t type: staff record counts by scanning barcodes instead of manual entry

- Barcodes by unit of measure (case/pack/can…): matches real-world packaging so counts are accurate and fast

- Instant sync to ERP: eliminates rekey errors and delays

With mobile + barcodes, chains routinely cut stocktake time by 60%+ and maintain ~3% COGS reduction over time.

Real-World Results: An Nhien Cafe

After adopting ERP with mobile counting + barcode reconciliation, An Nhien Cafe:

- Reduced stocktake time by 60%+

- Eliminated inventory fraud

- Cut COGS by ~3%, turning multiple locations from loss to profit

Read the full story: Acumatica ERP helps An Nhien Cafe increase profit & expand

Conclusion

F&B ERP is not just accounting—it’s a margin-protection shield. With daily reconciliation, clear variance reporting, and mobile barcode counting (incl. UoM barcodes), brands control ingredients down to the gram, reduce COGS by ~3%, and scale profitably.

Learn more: A complete solution: Core ERP capabilities for high-growth F&B chains

FAQ

How does ERP reduce shrinkage in F&B?

By enforcing a daily “sell → backflush → count → reconcile” loop, the system flags variances the same day, not month-end.

Why mobile app + UoM barcodes?

Scanning barcodes (case/pack/can) mirrors real packaging, speeds up counting 60%+, and removes rekey mistakes.

What success metrics should we expect?

F&B chains commonly report ~3% COGS reduction once daily reconciliation + mobile barcode is in place.